Applications

Our Solutions

Pyromeral’s materials find diverse applications from aerospace to motorsports. Notable applications include heat shields around engines, high-performance insulation in tight spaces, battery thermal runway containment, radomes, antennas, and exhaust ducts.

Space

PyroXide® is used on launch vehicles and in one application is used as a heat shield operating at 2425°F (1330°C) for 1 hour. PyroXide replaced a Titanium Zirconium Molybdenum (TZM) heat shield and saved 9.3 pounds per launch vehicle.

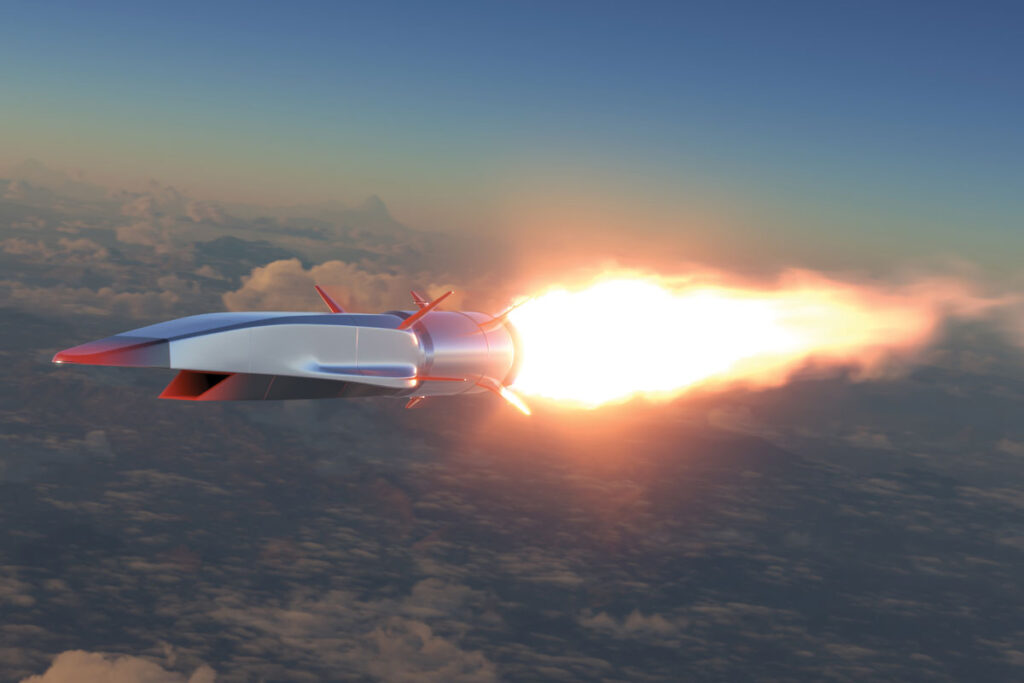

Hypersonics / Supersonics

Hypersonics have demanding requirements for strength and temperature. Pyromeral PyroXide® is exceptional for use as RF transparent nose cones, fins, and external skins. PyroXide’s high temperature resistance and radio frequency (RF) transparency makes it an excellent choice for use in radomes and antennas in supersonic aircraft and other broad-based defense applications.

eVTOL

Pyromeral materials have been successfully tested and validated for Li battery casings for Urbain Air Mobility vehicles and e-Aircraft. Our material solutions enable dramatic weight savings in fire protection areas of these vehicles, which enable increased flying range or higher payloads. For example, a 1 mm thin PyroKarb™ laminate passes the FAA kerosene burner test with no penetration at 2000°F after 15 minutes.

High-Performance Vehicles

Our materials are used in heat shields around engines and around brakes, which reach temps up to 1470°F and which also resist the high vibration from both the exhaust and chassis. For example, Pyromeral materials are used in F1 racing for parts to direct 1470°F engine exhaust gas to protect the CFRP sub-structure. A key advantage is that Pyromeral parts can be co-molded CFRP to put heat protection right where you need it.