Our Products

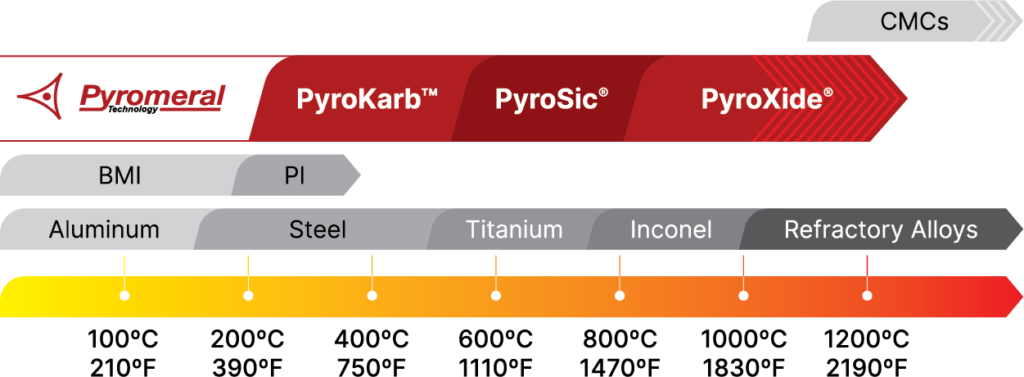

Pyromeral’s proprietary ceramic matrices, known as PyroKarb, PyroSic, and PyroXide, originate from alumino-silicate-based geopolymeric systems. These offer high-temperature performance with low-temperature processing, and mechanical properties comparable to CMCs making them practical, cost-effective, and environmentally compliant solutions.

Pyromeral’s family of products can be targeted to achieve performance for your specific application.

PyroKarb™

PyroKarb finds its home in industries such as motorsports, aerospace, defense, naval, and automotive applications. It serves as a versatile choice, either as a metal replacement for weight reduction or as a thermal barrier to enable CFRP structures.

-

Temperature Resistance:

PyroKarb can endure prolonged exposure to temperatures of 1110°F (600°C) and higher for short durations. This attribute ensures long-lasting performance under demanding conditions. -

Enhanced Fire, Smoke, and Toxicity Properties:

Safety is paramount. PyroKarb delivers superior fire resistance, low smoke emission, and reduced toxicity when subjected to heat or fire. For example, a 0.040 inch thin (1mm) PyroKarb laminate passes the FAA kerosene burner test with no penetration at 2000°F (1093°C) after 15 minutes. -

Complex Design Compatibility:

Whether it's intricate shapes or hybrid designs, PyroKarb can be molded to suit your unique requirements. It can be processed with many manufacturing techniques including hand lay-up, autoclave and out-of-autoclave, press molding, and filament winding. -

Dimensional Stability:

Maintaining structural stability at high temperatures is vital. PyroKarb holds its dimensional integrity even in extreme heat. -

Cost-Effective Implementation:

PyroKarb is not only an exceptional performer but also a total value solution compared to CMC alternatives.

PyroKarb™ is approximately 40% lighter than aluminum and 80% lighter than steel.

PyroSic®

PyroSic represents an innovative solution for industries seeking high-temperature resistance without sacrificing weight or performance. It’s a versatile choice for those looking to push the boundaries of what’s possible.

This composite is built on our proprietary glass-ceramic matrix system, reinforced with silicon carbide fibers. Key highlights of PyroSic include:

-

Remarkable Weight Savings:

PyroSic is a heavyweight contender when it comes to shedding pounds. It's twice as light as Titanium alloys and four times lighter than steel alloys or Inconel. -

Extreme Temperature Endurance:

With the ability to continuously withstand temperatures of 930°F (500°C) to 1470°F (800°C) PyroSic thrives in the most demanding environments -

Mechanical Prowess:

PyroSic doesn't compromise on strength. It excels in applications that demand exceptional mechanical strength, resistance to vibrations, and dimensional stability. -

Fuel Efficiency Booster:

Its superior performance and ability to replace heavy high-temp metallics, such as in exhaust areas, enhances fuel efficiency, a crucial factor in today's eco-conscious world and in the drive to NetZero. -

Versatility:

PyroSic's adaptability makes it suitable for an extensive range of applications, from UAVs to aircraft and more.

PyroSic’s weight savings is 75% compared to steel and 60% compared to titanium.

PyroXide®

PyroXide’s unique properties make it a valuable asset in the defense industry and the development of ultra-high-speed vehicles and ensuring safety in advanced air mobility vehicles. Its exceptional capabilities open doors to a wide range of applications.

PyroXide heralds a new era in oxide CMC materials. Developed in-house, PyroXide is built on Pyromeral’s proprietary oxide matrix, reinforced with aluminum oxide fibers. The exceptional features of PyroXide include:

-

Impenetrable Temperature Barrier:

PyroXide stands strong against elevated temperatures, boasting the ability to withstand 2190°F (1200°C) while retaining mechanical properties and to 2500°F (1370°C) for limited durations. -

Complex Geometries:

PyroXide prepreg’s ease of handling allows the manufacture of complex geometry composite parts. Complex exhaust nozzles and large-scale parts, such as wing skins exceeding nine feet, can be produced in one go, featuring aerospace-grade surface quality and impressive mechanical properties. Size is limited only by the autoclave, oven, and furnace size. -

Mechanical Excellence:

PyroXide shines with a flexural strength of 300 MPa, a modulus of 70 GPa, and an interlaminar shear strength exceeding 15 MPa up to temperatures of 1830°F (1000°C). -

Controlled Microstructure:

Unlike conventional Oxide-CMCs, PyroXide exhibits a microstructure with meticulously controlled microporosity. It virtually eliminates macroporosities and microcracks associated with thermal treatment. -

Radio Frequencies Prowess:

PyroXide showcases impressive Radio Frequencies properties, with an Epsilon’ value of 5.0 in the range of 8 GHz to 18 GHz and tandelta values from .0008 to .0018 in that range. PyroXide is an excellent solution for radar transparent nose cones and antenna on supersonic and hypersonic vehicles.

PyroXide is 70% lighter than Inconel and stainless steels and over 45% lighter than titanium.